3 Proper Preparation

3.1 Electrode Geometry

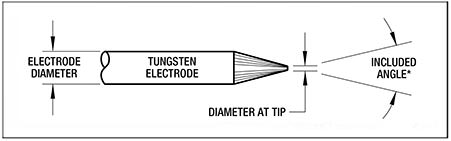

Tungsten electrodes may be used with a variety of tip geometries. In AC welding, pure or Zirconiated tungsten electrodes are usually used and are melted to form a balled end. This section of the guidebook is dedicated to grinding electrodes for DC welding. The complete geometry for DC welding is comprised of the electrode diameter, the included angle (a.k.a. taper) and the tip (flat) diameter. In addition, the surface finish of the grind is also important.

Figure 2: Electrode Geometry

Choosing the best electrode geometry requires compromise among various attributes such as: shorter to longer electrode life, easier to more difficult arc starting, deeper to shallower weld penetration, and wider to narrower arc shape (and thus bead shape and size as well). Whichever geometry is selected, it should be used consistently as part of a successful welding procedure.

For best results, electrode configuration should be tested while welding procedures are being developed; it should be noted as a critical process variable for the weld procedure; and close tolerances should be held for all subsequent welds.

Electrode Diameter: The welding equipment manufacturer’s recommendations are almost always the best way to choose which diameter electrode to use. There are also guidelines published by the American Welding Society, which are duplicated in Table 2 of this guidebook. Note that larger diameters can accommodate higher amperages; and larger diameter electrodes will last longer than smaller ones, but smaller ones will be easier to arc start. Use of higher current levels than those that are recommended for a given electrode size will cause the tungsten to deteriorate or breakdown more rapidly. As the tip erodes, the probability of tungsten particles falling into the weld pool and defecting the weld is much greater. If the current used is too low for a specific electrode diameter, arc instability can occur.

For a given level of current, direct current with the electrode positive requires a much larger diameter, because the tip is not cooled by the evaporation of electrons but heated by their impact; and thus it will become hot and subject to erosion. In fact, an electrode used with DCEP can handle approximately only 10% of the current that it could with the electrode negative. With AC welding, the tip is cooled during the electrode negative cycle and heated when positive. Thus, an electrode on AC can handle the current somewhere between the capacity of an electrode on DCEN and DCEP and about 50% less than that of DCEN.

Electrode Tip/Flat: The shape of the tungsten electrode tip is an important process variable in precision arc welding. A good selection of tip/flat size will balance the need for several advantages. The bigger the flat, the more likely arc wander will occur and the

more difficult it will be to arc start. However, increasing the flat to the maximum level that still allows arc start and eliminates arc wonder will improve the weld penetration and increase the electrode life. Some welders still grind electrodes to a sharp point, which makes arc starting easier. However, they risk decreased welding performance from melting at the tip and the possibility of the point falling off in the weld pool. In situations where very low amperage is used or short weld cycles are used (i.e., one second or less), a pointed electrode is desirable; however, for other situations it would be beneficial to prepare a flat at the end of the electrode.

Guidelines for testing can be found in Table 6; also refer to the welding equipment manufacturer’s recommendations. During the welding operation, the accurately ground tip of a tungsten electrode is at a temperature in excess of 3000° C (5500° F). Incorrect or inconsistent diameter flat at the tip of the tungsten electrode can lead to the following problems:

- Pointed electrode tip drops into weld pool creating weld defect

- Reduction in electrode life

- Arc instability

- Change in arc voltage from one electrode to another due to inconsistent tip shape

In AC welding, pure or Zirconiated tungsten electrodes melt to form a hemispherical balled end. For DC welding, Thoriated, Ceriated, or Lanthanated tungsten electrodes are usually used. For the latter, the end is typically ground to a specific included angle, often with a truncated end. Various electrode tip geometries affect the weld bead shape and size. In general, as the included angle increases, the weld penetration increases and the width of the weld bead decreases. Although small diameter electrodes may be used with a square end preparation for DCEN (Direct Current Electrode Negative) welding, conical tips provide improved welding performance.

Table 6: Tip Recommendations by Electrode Diameter Size

| Electrode Diameter | General Tip Recommendations |

| .020” (0.5mm) | 0 – .005” |

| .040” (1.0mm) | 0 – .020” |

| 1/16” (1.6mm) | 0 – .030” |

| 3/32” (2.4mm) | .005” – .030” |

| 1/8” (3.2mm) | .010” – .040” |

| 5/32” (4.0mm) | .010” – .050” |

| 3/16” (4.8mm) | .010” – .060” |

| ¼” (6.4mm) | .010” – .070” |

Electrode Included Angle/Taper: Electrodes for DC welding should be ground longitudinally and concentrically with diamond wheels to a specific included angle in conjunction with the tip/flat preparation. Different angles produce different arc shapes and offer different weld penetration capabilities. In general, blunter electrodes that have a larger included angle provide the following benefits:

- Last Longer

- Have better weld penetration

- Have a narrower arc shape

- Can handle more amperage without eroding.

Sharper electrodes with smaller included angle provide:

- Offer less arc weld

- Have a wider arc

- Have a more consistent arc

Larger tungsten diameters and higher currents are normally paired with larger tapers in the 25° to 45° included angle range in order to increase electrode service life and provide a more stable arc. More pointed tips in the 10° to 25° included angle range are used for lower current.

Electrode Angle Surface Finish: The smoothness of the finish on the prepared tip of the electrode will determine some of the characteristics of the welding process. In general, points should be ground as fine as possible to improve welding properties and increase the service life of the electrode. Electrodes that are ground too coarse result in unstable arcs.

Surface finish is typically expressed as a Root Mean Square (RMS) or as a Roughness Average (Ra). RMS is a comparative number as related to surface finishes measured with a profilometer. A fine finish is in the range of 20-40 RMS, a machined finish often is in the range of 80-120RMS, and gritblasted surfaces will be in the range of 400-500 RMS. The Ra value is defined as the average value of the departures from its centerline through a prescribed sampling length. Measured values expressed as RMS will read approximately eleven percent higher than values expressed in Ra. (Microinches x 1.11 = RMS).

A standard finish of around 20 RMS, which would still show the longitudinally ground lines to the naked eye, is an all-purpose, quality finish for any application. A highpolished, or mirror-like finish of approximately 6-8 RMS, where few or no lines can be seen, is better for the longevity of the electrode because without any grit to the electrode surface, it is much less likely for contamination to “stick” to the electrode point and thus less erosion takes place. However, for welding power supplies that do not have strong arc starting characteristics, a finish of approximately 20 RMS is better because the longitudinally ground lines will help steadily lead the electrons to the extreme point of the electrode which assists in arc starting. Some manufacturers of preground welding electrodes provide coarser finishes in the 30 to 40 RMS ranges; however, these do not last long, they provide unstable arcs, and they tend to be too

gritty for extended, effective arc starting.

Typical Manufacturers’ Recommended Geometries: Many manufacturers provide information on recommended electrode geometries, because they have already preformed testing to determine which electrode geometry is the most beneficial for their equipment in various applications. However, when this information is not available, Diamond Ground Products, Ltd. or other industry experts are the best source for this information.

Tolerances Required for Different Applications: Many welding applications are deemed highly critical and require strict tolerances on the length, taper, and flat, in addition to a high-polished finish. These applications include orbital tube welding for high purity, pharmaceutical, aerospace applications, fitting manufacturing, and many others. Basic guidelines for tolerances in these applications are ± .002” for the length, ±½° for the taper, and ± .002” for the tip/flat. Where applications require electrodes to be manufactured to these extreme tolerances, it is necessary to use equipment such as an optical comparator, microscope, and micrometer in addition to the precision tungsten electrode grinder which is required for almost all applications. Other applications will often call for their own specific tolerances. Where not specified, keep reasonable tolerances for the type of work being performed and remain as consistent as possible.

3.2 The Proper Equipment

In most applications, it is very important that a dedicated, custom tungsten electrode grinder is used. Other grinding equipment that may be available at a typical facility either typically does not offer the means for proper longitudinal diamond grinding nor consistency of preparation from one electrode to the next. As a result, they will take up too much of a welder’s costly time to produce an electrode that may not weld or weld for very long. In addition, a non-dedicated machine will be contaminated with foreign material because it is used for grinding parts other than tungsten. This will contaminate the electrode and cause welding problems.

Refer to Table 7 to determine whether a piece of equipment will efficiently produce consistent and repeatable electrodes and welds.

Table 7: Questions to Ask to Determine a Proper Electrode Grinder

| Question | Conditions |

| Does it grind longitudinally? | A necessity |

| Does it incorporate a diamond-grinding wheel? | A necessity |

| How many electrodes can a typical diamond grinding wheel make before requiring replacement? | The more the better. This also varies based on operator use. |

| If a cutting apparatus is needed, does it offer a diamond-cutting wheel with measurement apparatus? | Notching the electrode and hand breaking is not acceptable |

| How short can the electrode be cut? | Match this condition to your needs. |

| What is the surface finish to the electrode after grinding? | 20 RMS is fine for most uses, finer finishes are even better. |

| How quickly does it take to flat, grind, and cut a typical electrode? | A .040” diameter electrode should not take more than 60 seconds after setup. |

| What is the process for setup to flat, grind, and cut different electrode diameters, angles, flats, and lengths? | It should sound simple and direct. Otherwise, it will take too long and become cumbersome. |

| What is the process the equipment operator needs to follow to complete one electrode? | It should simple enough that all welders can repeat the process and produce the same electrode. |

| What tolerances can a typical operator expect to produce for the angle, length, and flat? | Match these to your needs. |

| Are accessories such as vacuum dust collection, on site carrying case, a wide variety of collets, etc. readily available? Is support readily available? What is the warranty? | Match these to your needs. |

| How expensive is it? | Expect to pay quite a bit more than a standard bench grinder, but a good tungsten grinder will pay for itself over time with saved welding time, saved electrode preparation time, and improved welds. |

3.3 Proper Grinding and Cutting Techniques

Tungsten electrodes are the crucial electrical carrier in the welding process, and they must be ground and cut properly. Improperly prepared electrodes can lead to arc wander, splitting, shedding, welding inconsistencies, or expensive mistakes. Properly ground and cut electrodes can improve arc starting and stability.

Always use diamond wheels when grinding and cutting. While tungsten is a very hard material, the surface of a diamond wheel is harder, and this makes for smooth grinding. Grinding without diamond wheels, such as aluminum oxide wheels, can lead to jagged edges, imperfections, or poor surface finishes not visible to the eye that will contribute to weld inconsistency and weld defects. Also, welders should avoid contact of the electrode with the weld pool. If this does happen, the contaminated portion of the tip should be cut off, the electrode should be reground from the beginning.

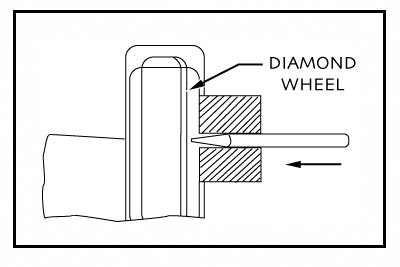

Tip/Flat Preparation: When preparing a flat from a used electrode, if the end to be ground is exceedingly contaminated, the old tip it should be cut off before preparing the flat. Figure 3 illustrates how to recondition an electrode with minimal contamination. This procedure would also work with a new electrode or an electrode with the contamination cut off. Simply push the electrode at exactly a 90° angle to the side of the wheel. There should be an apparatus to hold the tungsten so that the angle is maintained.

Note: New electrodes and cut electrodes already have a flat at the tip of the electrode.

Figure 3: Reconditioning an Electrode

Table 8: Tungsten Electrode Tip Shapes and Current Ranges

| Electrode Diameter | Diameter At Tip | Included Angle | DCEN Constant Current Range,A | DCEN Pulsed Current Range, A |

| .040” / 1.00mm | .005” / .125mm | 12 | 2 to 15 | 2 to 25 |

| .040” / 1.00mm | .010” / .25mm | 20 | 5 to 30 | 5 to 60 |

| .060” / 1.60mm | .020” / .5mm | 25 | 8 to 50 | 8 to 100 |

| .060” / 1.60mm | .030” / .8mm | 30 | 10 to 70 | 10 to 140 |

| .093” / 2.40mm | .030” / .8mm | 35 | 12 to 90 | 12 to 180 |

| .093” / 2.40mm | .045” / 1.1mm | 45 | 15 to 150 | 15 to 250 |

| .125” / 3.20mm | .045” / 1.1mm | 60 | 20 to 200 | 20 to 300 |

| .125” / 3.20mm | .060” / 1.5mm | 90 | 25 to 250 | 25 to 350 |

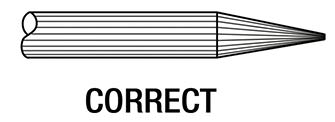

Taper Grinding: The most important element of proper taper grinding is that the electrode must be ground longitudinally (lengthwise). Grinding electrode tips crosswise has a negative effect on the stability and formation of the arc at the electrode tip. Tungsten electrodes are manufactured with the molecular structure of the grain running lengthwise and thus grinding crosswise is “grinding against the grain.” More importantly, electrons flow at a greater density on the surface of the electrode. If electrodes are ground or polished crosswise, the electrons have to jump across the grinding marks. The arc begins before the tip, spreads out, and usually wanders. The tungsten electrode becomes overheated and wears out more quickly. By grinding longitudinally with the grain, the electrons are led steadily and with less difficulty to the extreme tip of the tungsten electrode. The arc starts straight and remains narrow, concentrated, and stable. The electrode is subjected to less Thermal shock, and therefore lasts longer. Figure 4 provides an example of correct and incorrect grinding.

Figure 4: Correct and Incorrect Grinding

Lengthwise grind marks do not restrict current. Mirror finish preferred.

Crosswise grind marks restrict welding current, cause arc wander, and risk

inclusions

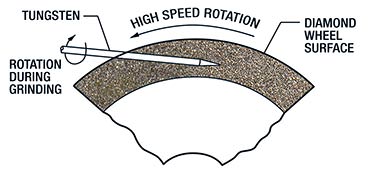

For the best possible arc stability, diamond grinding of tungsten electrodes should be done with the length of the electrode at a 90° angle to the axis of the grinding wheel as shown in Figure 5. The diamond-grinding wheel should not be used for grinding anything other than tungsten to ensure that the wheel and thus the tungsten tip will not become contaminated during the grinding operation and then transfer that foreign material to the weld.

Note: An exhaust system should be used when grinding Thoriated electrodes toremove the grinding dust from the work area.

Figure 5: Electrode at 90° Angle to Grinding Wheel

Cutting to Length: One of the most overlooked areas of tungsten electrode preparation is the cutting operation or contaminated tip removal. Contaminated tungsten electrode tips are a common problem that confronts TIG welders. A contaminated electrode produces an erratic arc and a dirty, contaminated weld. The best way to ensure that all contamination is removed from the tip is to cut off that part of tungsten. Regrinding a contaminated tip may not remove all of the contamination, and it can deposit the contamination on the grinding wheel, only to be picked up again in future grinding.

Because tungsten is a very hard material, proper cutting involves using a diamondcutting wheel for consistent, clean cuts. Many welders cut their tungsten incorrectly using one of the following methods:

- For .040” and 1/16” diameter electrodes: using wire cutters or hands to break electrodes.

- For 3/32” or 1/8” diameter electrodes: using two pairs of pliers and a twisting motion or notching the electrode on the grinding wheel and then breaking the electrode by hand or with pliers

- For electrodes larger than 1/8” diameter: using a sharp hammer blow to the electrode on a sharp metal edge or notching the electrode on a grinding wheel and then hitting with a hammer on a sharp metal edge.

All of these methods risk safety and weld problems. The electrode can be splintered or shattered without the welder noticing it. Fractured electrodes can lead to arc instability, parts of the tungsten dropping into the weld pool creating a weld defect, and other problems. Also, if the tungsten shatters there is the risk of eye or hand injury. In any case, it is much easier to cut an electrode quickly and properly with the correct cutting apparatus designed specifically for how hard and brittle tungsten is.

The cutting apparatus should keep the tungsten rigidly secure on either side of the cut for stability and so that the cut is exactly at a 90° angle. Using a diamond cutting wheel will ensure that the cut will be clean and smooth and void of fractures or splintering. A silicon carbide wheel should never be used as it can contaminate the tungsten. The apparatus should be quick and easy to use, have safety covers, and provide a scale to ensure the exact length is measured and cut.

3.4 Safety Suggestions

Tungsten welding electrodes should never be manually ground on an abrasive belt or wheel (particularly silicone carbide). The risk of injury when hand (manually) grinding a very hard brittle material like tungsten is quite high. Always follow standard safety guide lines when operating high speed grinding equipment.

- Use approved safety glasses

- Do not wear loose clothing which may get caught in moving parts

- Wear protective hair covering to contain long hair

- Wear safety shoes with non-slip sole

- Whenever possible, use a vacuum system to remove tungsten and thorium dust generated in the work area.

- Never operate power tools when tired, intoxicated, or when taking medication that causes drowsiness

Hand and glove protection is strongly recommended, because the most common injuries are to the fingers and eyes. Holding and grinding the tungsten electrode by hand can result in burned fingers, laceration to fingers, and splintered tungsten electrodes in hand or fingers. Eye injury generally occurs from manually grinding tungsten electrodes without a safety shield or safety glasses. Small slivers of tungsten electrode may become stuck in the operator’s eye.