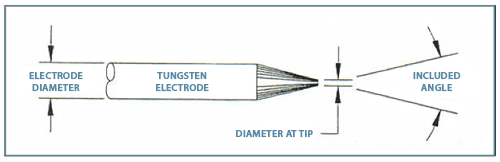

Diamond Ground Products’ longitudinally prepared pre-ground welding electrodes are made to your exact specifications and offer improved arc starting and stability, greater longevity and consistent welds at economical prices.

Applications

Pre-ground electrodes are ideal for strict tolerance applications such as

- Semiconductors/clean rooms

- Aerospace

- Pharmaceutical

- Nuclear

- High purity gas and liquid delivery systems

- and many more…

Pre-ground tungsten electrode materials

DGP have a wide variety of electrode materials in stock (Material specifications and certification are available on request), including:

- Tri-Mix Tungsten

- 2% Lanthanated Tungsten

- 2% Ceriated Tungsten

- 2% Thoriated Tungsten

- Cryo-T, Pure, Zirconiated

- 0.20″ to 1/4″ diameter

Increase weld quality and consistency –

keep your welders more productive!

|

|

|

|

Why use Pre-ground Tungsten Electrodes?

|

|

|

|

|

|

|